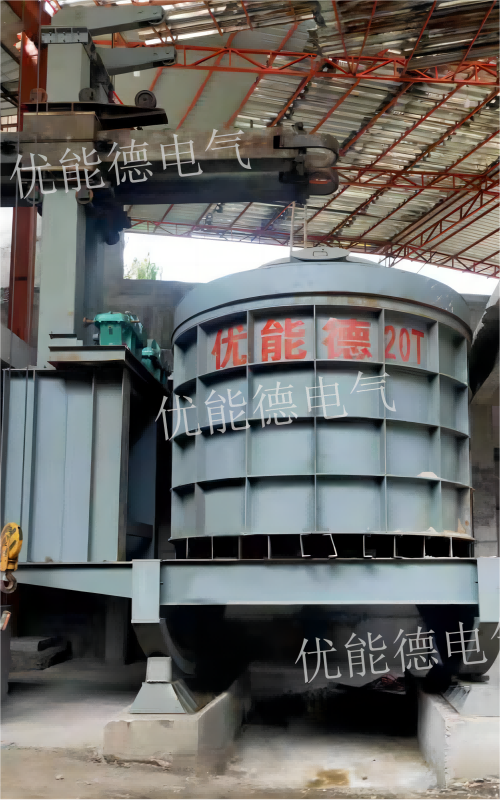

Ironmaking DC Submerged Arc Furnace 100~20000kVA

Get the latest price? We will respond as soon as possible(within 12 hours)

- Information

- Product Description

- Video

Submerged arc furnace is a new type of ironmaking equipment. It uses a high-temperature electric arc to heat the iron ore in the furnace to a molten state, while creating a reducing atmosphere in the furnace, thereby converting the iron ore into molten iron. The specific working principle is as follows:

1. Preparation work: Mix iron ore and other auxiliary raw materials (such as coke, limestone, etc.) in a certain proportion to make pellets.

2. Feeding: The pellets are fed into the submerged arc furnace through the feeding system.

3. Heating: A high-temperature arc is generated in the submerged arc furnace, and the iron ore in the furnace is heated to a high temperature through the arc.

4. Smelting: The raw materials that reach the reaction temperature react with carbon to produce a series of metallurgical reactions, reducing the iron element in the raw materials to metallic iron. Metal iron melts into molten iron and gathers at the bottom of the furnace.

5. Collection: Collect molten iron from a submerged arc furnace, usually by dumping the furnace body or using a molten iron ladle for collection.

Submerged arc furnaces have advantages such as high temperature, high efficiency, and flexibility, and are widely used in metallurgical industries such as steelmaking and ironmaking. It can adapt to the smelting requirements of various iron ores and raw materials, and can also flexibly adjust production processes and scale, with high production efficiency and economy.